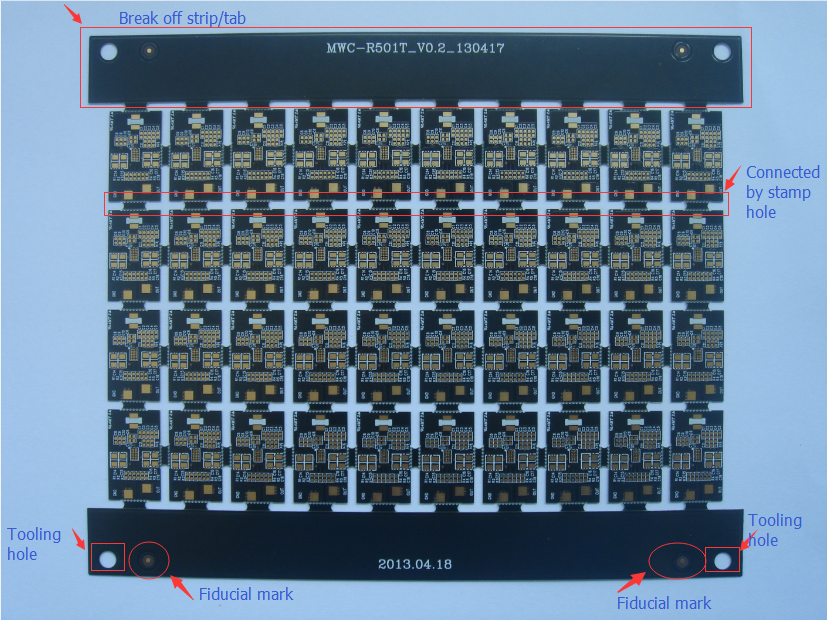

PCB’s must have a break off area to allow for conveyor machines throughout the factory. Break off width must be a minimum of 10mm from the edge of the board and must run along the longest edge of the PCB.

Tooling strips are the break-off areas to hold the PCB on the automated conveyers throughout the factory. PCB must have tooling holes to secure it to its particular work table whilst being populated. The hole size and position will be as follows:

Hole size: 4.0mm

Location: All 4 corners of PCB with center of hole 5mm from both edges.

This tooling hole is mostly situated in the break off area on the edges of the PCB and will normally be done automatically by the PCB manufacturer.

Please state to PCB manufacturer that the PCB’s are going to Wonderful for manufacture and the PCB’s will be produced correctly with tooling strips and tooling holes.

Fiducial marks are required for the automated placement of all SMT components. They are used as reference points by Auto placement machines to establish XY co-ordinates for accurate component placement.